Process:

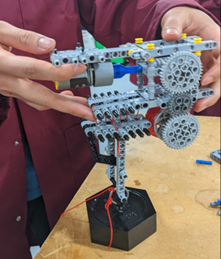

We decided to make a gantry crane to manouver the mass across the obstacle.

We then split the components needed to create the crane amongst the group members. They were: Main Structure, pulley system and gear train, the cart and the lateral movement of said cart.

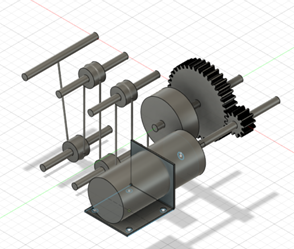

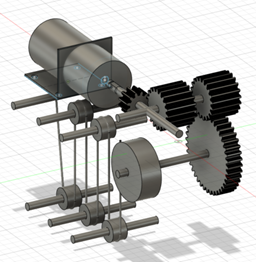

Alongside 1 other group member I was in charge of completing the pulley system and gear train in a manner that it could be easily attached to the cart created by another group.

We chose a 1:5 pulley system and the use of bevel gears to at a 3:10 gear ratio to get the most leverage in the space we had to work with.

Skills

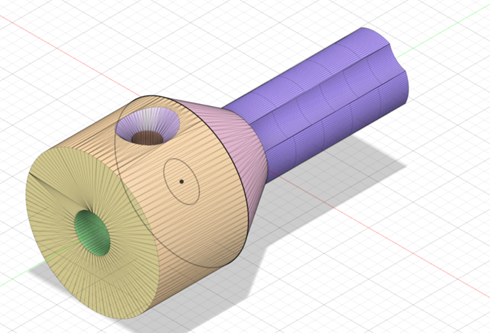

- Fusion 360

- Teamwork

- Problem Solving

- 3D Printing using Ultimaker Cura

Project Outcome

Results:

In the end, our gantry crane was able to complete the required task of moving the mass over the defined object.

Improvements:

To improve the gear and pulley section we should have paid more attention to the physical prototyping stage of the gears as we compounded the gears resulting in a 3:4 ratio rather than the intended 3:10.

Below are links to the pulley and gear train section of the full report and also my personal reflection section.

Unfortunately, I was not able to link the entire report.